mirror of https://github.com/foostan/crkbd.git

209 lines

6.8 KiB

Markdown

209 lines

6.8 KiB

Markdown

# Build Guide

|

|

|

|

This is the build guide for Corne Light v2 Low edition.

|

|

|

|

|

|

|

|

|

|

|

|

## Parts

|

|

|

|

### Required

|

|

|

|

| Name | Count | Remarks |

|

|

|:-|:-|:-|

|

|

| PCB | 1 set | |

|

|

| Top plate (acrylic) 2mm | 2 sheets | |

|

|

| Bottom foam | 2 sheets | Special foam is cut out with a special mold |

|

|

| OLED protective plate | 2 sheets | |

|

|

| ProMicro | 2 sheets | |

|

|

| TRRS jack | 2 | |

|

|

| Tact switch | 2 | |

|

|

| Diodes | 42 | Recommended SMD Parts |

|

|

| Key switches | 42 | Kailh Choc v1 or v2 recommended |

|

|

| Keycaps | 42 pcs | 1u 40 pcs, 1.5u 2 pcs |

|

|

| Spacer M2 9mm | 4 pieces | |

|

|

| Screw M2 4mm | 8 screws | |

|

|

| TRRS (4 poles) cable | 1 | TRS (3 poles) cable is also acceptable |

|

|

| Micro USB cable | 1 | |

|

|

|

|

### Optional

|

|

|

|

| Name | Count | Remarks |

|

|

|:-|:-|:-|

|

|

| OLED module | 2 sheets | |

|

|

| Pin header for OLED module 4 series 1.5mm | 2 | |

|

|

| 4 pin sockets for OLED module 2.5mm | 2 | |

|

|

|

|

## Advance preparation

|

|

|

|

If you build the firmware yourself,

|

|

it takes time to prepare the environment,

|

|

so it is recommended to start first. \

|

|

See <https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>

|

|

for more information.

|

|

|

|

## Verification

|

|

|

|

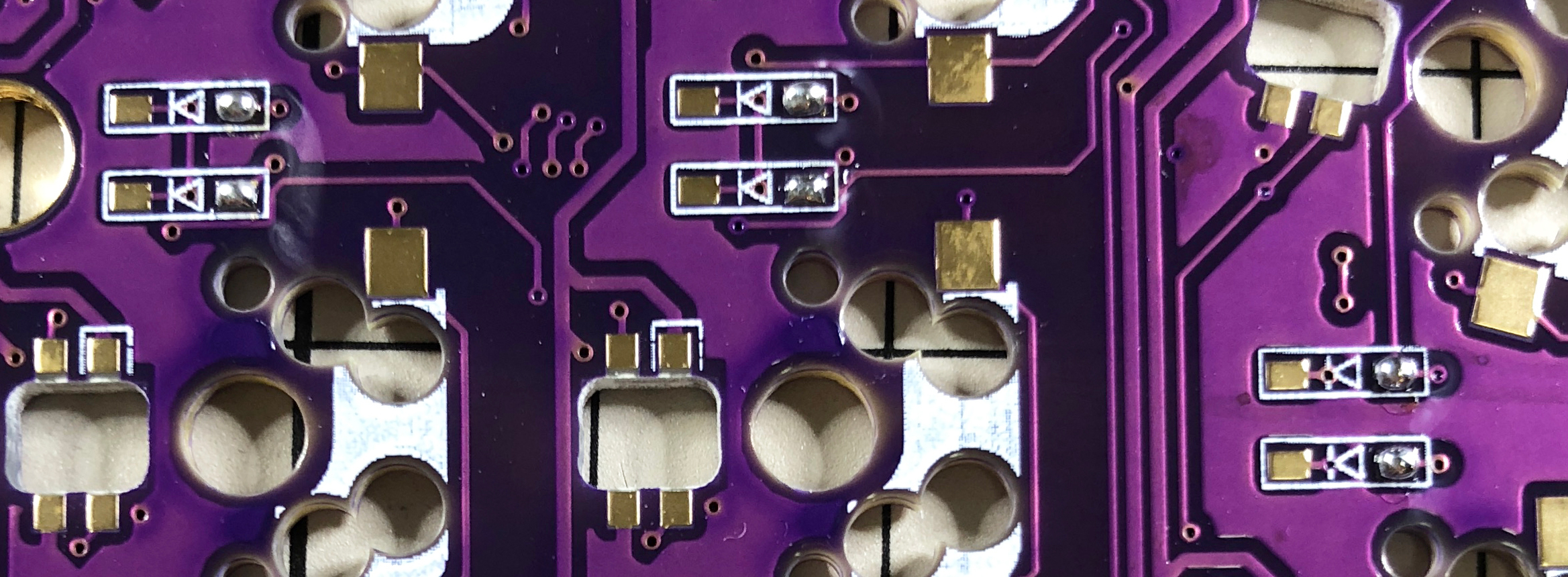

The PCB for Corne Light v2 is as follows.

|

|

Make sure it is the same as your PCB.

|

|

|

|

|

|

|

|

|

|

|

|

The PCB comes with a frame for manufacturing reasons.

|

|

You can fold it by hand to remove it, but if it is difficult,

|

|

make a cut in the joint \* with a cutter or similar,

|

|

to make it easier to remove.

|

|

In addition, the joint can be cleaned with a file.

|

|

|

|

\* *Joint part: There are a total of 8 parts,

|

|

which are marked in red in the image below.*

|

|

|

|

|

|

|

|

## Assembly

|

|

|

|

### Diodes

|

|

|

|

Solder diodes for SMD components.

|

|

Since SMD parts are very small,

|

|

it is convenient to have tweezers and counter-acting tweezers.

|

|

|

|

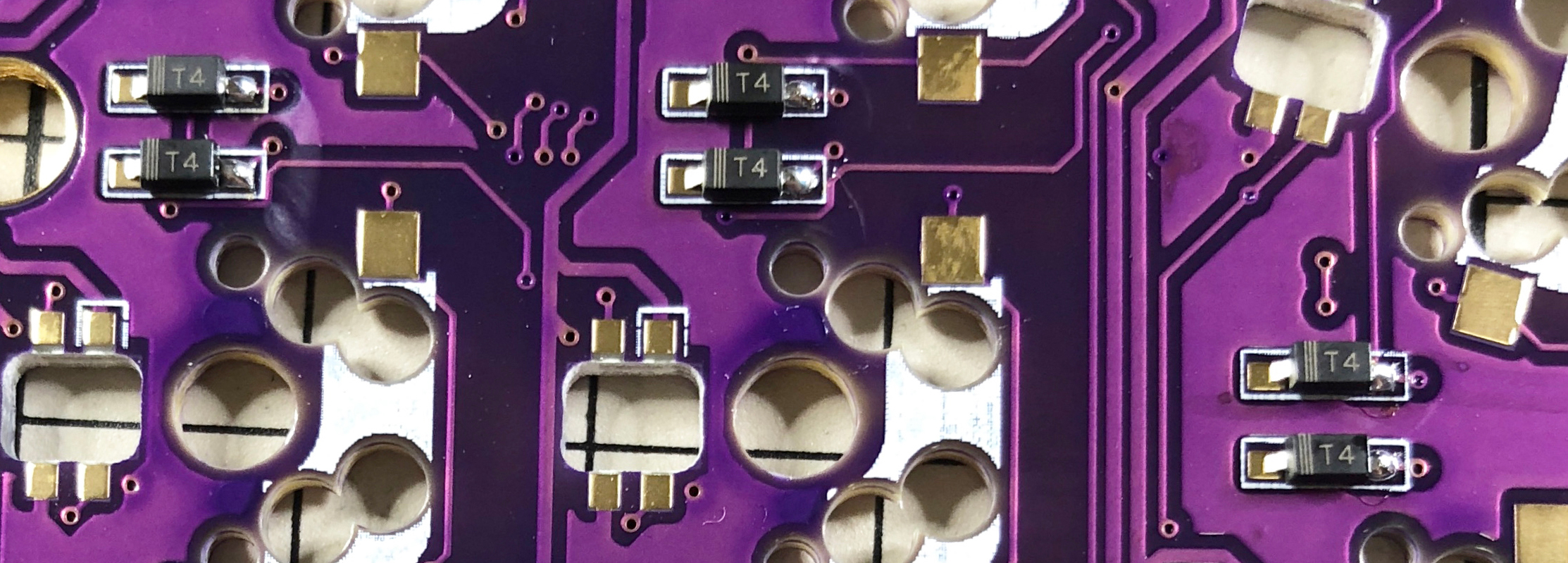

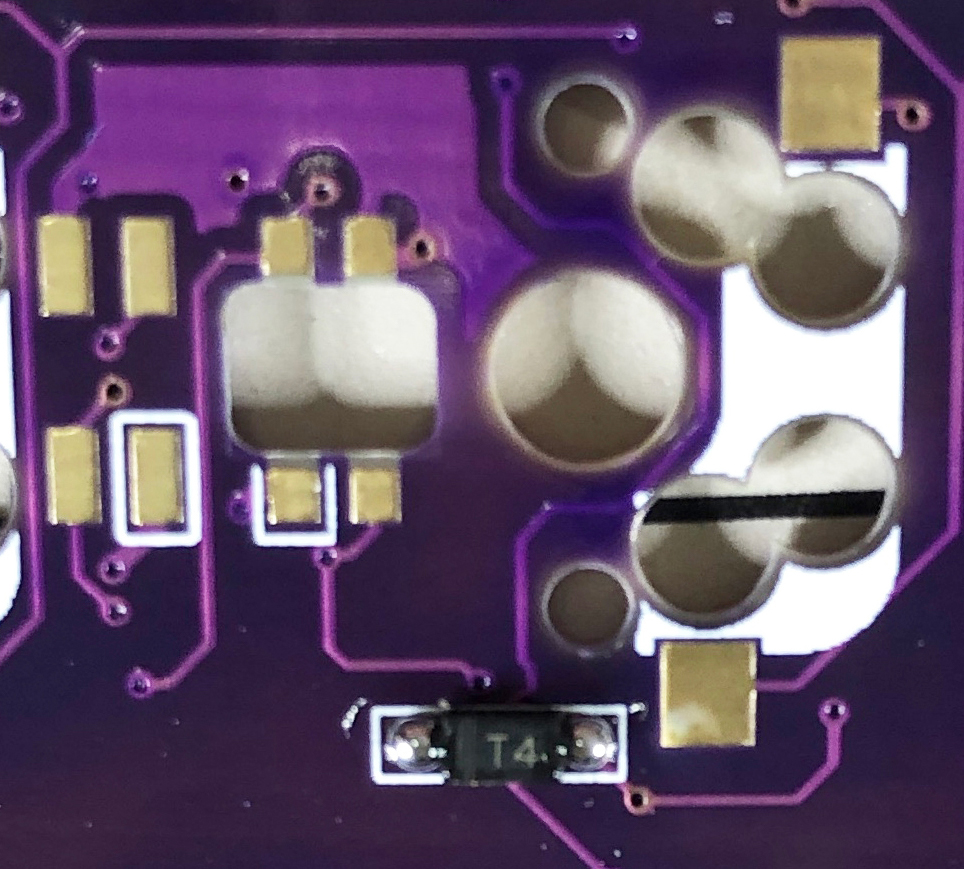

**The diode has a fixed mounting direction**,

|

|

so solder it so that the "|" mark on the part faces the "|" on the diode mark "|◁".

|

|

In addition, Corne's PCB has all the same diode mounting orientations.

|

|

|

|

|

|

|

|

<details>

|

|

<summary>TIPS: Tips for installing SMD parts</summary>

|

|

|

|

The trick is to attach the SMD parts, but first, as a spare solder,

|

|

put the solder on only one side of the pad.

|

|

|

|

|

|

|

|

Next, solder one leg of the diode so that the spare solder melts.

|

|

At this time, it is recommended to use reverse-action tweezers,

|

|

because you can hold the chip parts firmly without exerting force

|

|

and you can concentrate on alignment and soldering.

|

|

Also, if the soldering iron is too hot or the solder is touched too much,

|

|

the flux contained in the solder may evaporate and form a clean pile of solder,

|

|

but it can be repaired later,

|

|

so at this point you should only care about attaching parts.

|

|

It's okay.

|

|

|

|

|

|

|

|

It is okay if the diode does not float when viewed from the side

|

|

when one foot is attached.

|

|

If it floats, press the diode with tweezers or your fingers

|

|

and reheat the soldered part with a soldering iron to clean it.

|

|

|

|

|

|

|

|

Then solder the other one.

|

|

Be careful not to apply too much,

|

|

as a small amount of solder is sufficient.

|

|

If you apply too much, you can remove it with a blotting wire

|

|

or by scooping it with a soldering iron.

|

|

|

|

If the amount of solder on the preliminary solder side is small,

|

|

additional soldering is performed, and if it is a mountain,

|

|

apply flux from above and heat it to clean it.

|

|

|

|

|

|

|

|

</details>

|

|

|

|

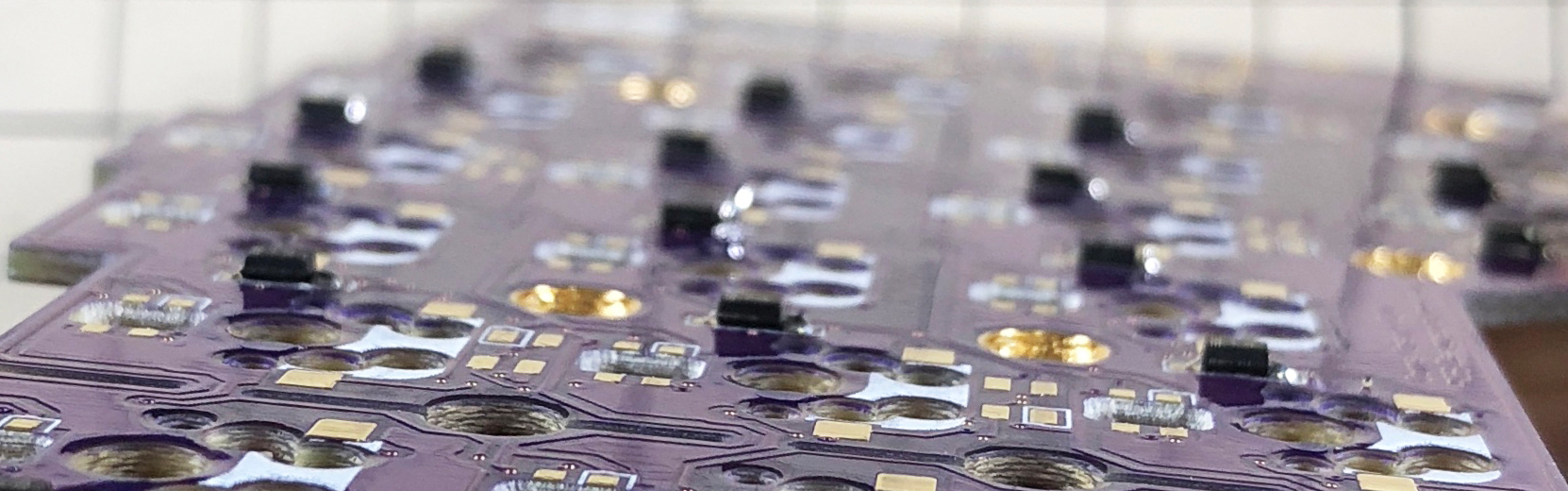

The diode is completed by soldering 42 pieces in total on the left and right.

|

|

|

|

|

|

|

|

### TRRS jack, reset switch, pin socket for OLED

|

|

|

|

Solder the TRRS jack, reset switch (tact switch),

|

|

and OLED pin socket as shown in the picture below.

|

|

|

|

|

|

|

|

Since it is a part that easily slips off,

|

|

you can solder it while holding the part by hand,

|

|

or fix it with masking tape and then solder it.

|

|

|

|

### ProMicro

|

|

|

|

Solder ProMicro in the following orientation

|

|

|

|

|

|

|

|

If you use spring-loaded pin headers (e.g. Conthrough),

|

|

you do not need to solder the back side.

|

|

Please refer to the [Helix Build Guide](

|

|

https://github.com/MakotoKurauchi/helix/blob/master/Doc/buildguide_en.md#pro-micro)

|

|

for details on how to use spring-loaded pin headers.

|

|

|

|

|

|

|

|

### OLED module

|

|

|

|

Insert the pin header into the pin socket for OLED first,

|

|

and then solder the pin header and OLED module.

|

|

At this time, the OLED module is easy to float,

|

|

so be careful not to float it while pressing it with your finger.

|

|

|

|

|

|

|

|

### Firmware

|

|

|

|

Write the firmware to ProMicro by referring to the following. \

|

|

<https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>

|

|

|

|

### Operation check

|

|

|

|

We recommend that you check the operation when the ProMicro and OLED module are attached.

|

|

If you do it at the very end, it will be difficult to isolate the problem.

|

|

|

|

To check the operation,

|

|

connect the left hand side to the PC with MicroUSB,

|

|

and connect the left hand side and the right hand side with the TRRS cable.

|

|

Since there may be defects such as jacks,

|

|

be sure to connect the left and right instead of one by one

|

|

before checking the operation.

|

|

If it is done correctly so far,

|

|

if you short the pad to attach the PCB socket with tweezers etc.,

|

|

the key pressed on the OLED module will be displayed.

|

|

|

|

### Top plate, switch

|

|

|

|

After attaching the key switch to the top plate, solder the key switch.

|

|

If you attach all the key switches to the top plate first,

|

|

it will be more difficult to attach the switches to the board,

|

|

so it is easier to attach only the end key switches first.

|

|

|

|

|

|

### OLED protective plate

|

|

|

|

Attach the OLED protective plate with M2 9mm spacers and M2 screws.

|

|

|

|

|

|

|

|

|

|

Especially for the screws on the back side,

|

|

tighten them firmly to attach the bottom foam after this.

|

|

|

|

### Bottom form

|

|

|

|

Finally, paste the bottom form.

|

|

This foam has an adhesive surface on one side

|

|

and a non-slip surface on the other side.

|

|

Stick the adhesive side firmly to the PCB.

|

|

|

|

|

|

|

|

That's it.

|

|

|

|

|